White UF Resin Adhesive Powder

- Product Information

Advanced high-tech processing of ordinary wood, especially fast growing species transforms it into our Restructuring Tech-wood which meets aesthetic and functional interests of diverse customers. Molding of this wood is carried out with the aid of specially formulated urea-formaldehyde resin glue and then undergoes gluing, curing and heat treatment processes to produce a quality finished product. The technical wood veneer’s water resistance and weather durability are significantly improved by this type of adhesive. As top-ranking China UF Resin Adhesive Powder Manufacturer, we strive to fit in the market with high-quality products that can satisfy various demands. You may send your inquiry and look at our competitive quotation as you partner with a trusted China Restructuring Tech-wood Manufacturer for guaranteed results.

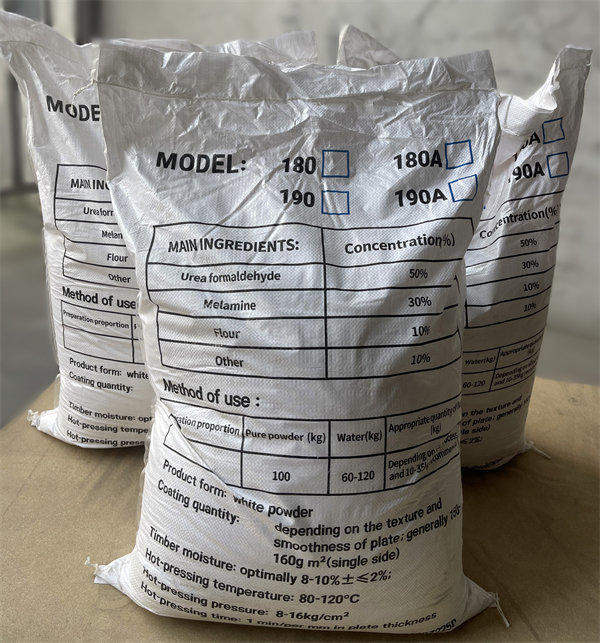

White UF Resin Adhesive Powder Parameters:

| Name | Urea Formaldehyde Resin Powder |

| Model | 180/180A |

| Shelf life | 1 year |

| Product form | white powder |

| Weight | 25kg |

| Timber moisture | optimally 8-10%±≤2% |

| Hot-pressing temperature | 80-120℃ |

| Hot-pressing pressure | 8-16kg/cm² |

| Hot-pressing time | 1 min/per mm in plate thickness |

| Performance | Boiled at 80℃ for 2.5 hours(180) / Boiled at 80℃ for 3.5 hours(180A) |

| Amount of curing agent added | 2-5‰ of the glue already blended |

| Without curing agent, activity period(180) | 24 hours |

| Industrial flour has been added, activity period(180A) | 24 hours |

| Without industrial flour and curing agent, activity period(180A) | 48 hours |

| Curing agent has been added, activity period | 3 hours |

| Coating quantity | depending on the texture and smoothness of plate, generally 150-180g m²(single side) |

White UF Resin Adhesive Powder Instructions For Use:

1. Prepare a container, stirring tools, and 25kg of room temperature water (add the water twice).

2. Dissolving glue powder:

First pour 15kg of water into the container,

then pour 25kg of resin powder into the water and stir to dissolve.

Stir into a paste until the glue powder does not agglomerate,

then add the remaining 10kg of water and fully stir to form a glue solution.

3. The mixed glue is used after 1 hour of waiting, and the effect is the best.

4. According to the production requirements of the product process, it can be mixed with additives such as curing agent(Ammonium chloride) .

5. During use, increase or decrease the ratio of resin powder to water according to the moisture content of the board and the local climate.

6. Amount of industrial flour added: 20-25% of the glue already blended.(180A to add)

White UF Resin Adhesive Powder Features:

1. Advanced Wood Restructuring for Unique Designs

UF Resin Adhesive Powder for Restructuring Technology Veneer leverages leading technology to convert normal timber, even fast-growing varieties, into extremely versatile and beautiful products. This provides an opportunity to create one-of-a-kind patterns and textures that are ideal for novel designs. Rely on our Board UF Resin Powder to ensure every piece of tech-wood remains firmly bonded.

2. Superior Weather Resistance

Our Restructuring Tech-Wood, with the addition of our specialized Particleboard UF Resin Powder, is made to withstand harsh environmental conditions. The resin makes the wood more resistant to moisture, humidity and temperature changes resulting in a finished product that is durable and reliable even in the most demanding applications.

3. Eco-Friendly and Sustainable Solutions

We make sure that we use fast growing wood species in manufacturing our Restructuring Tech-wood so as to reduce ecological impact. Moreover, the application of Board UF Resin Powder during production process guarantees compliance with eco-friendly standards thus providing great options for environmental friendly projects.

4. Versatile Applications Across Multiple Industries

In furniture, interior design or construction, our Restructuring Tech-Wood offers a range of solutions suitable for different industries. Our robust bonding strength provided by our Particleboard UF Resin Powder enables it to be used across various fields hence giving room for a functional yet visually appealing final product.

5. Reliable Quality and Consistency

Every batch of Restructuring Tech-wood rolled out from here meets the highest quality and consistency standards since we are among the industry frontrunners in this field. These structural components maintain its integrity because they contain elements such as Board UF Resin Powders, thereby offering consistent performance throughout all your projects you have undertaken since inception till now—guaranteeing reliability at every turn!

White UF Resin Adhesive Powder Application:

Furniture Manufacturing: Our Restructuring Tech-wood is perfect for various kinds of furniture fabrication that come with high quality which can be customized and provide unique designs while maintaining strength and durability factors. The use of modern synthesis urea-formaldehyde adhesive prevents the wood from delaminating over time.

Interior Decoration: Our Restructuring Tech-wood offers a variety of textures and finishes which make it perfect for wall panels, moldings, and other decorative elements. Additionally, it has excellent resistance to weathering hence suitable for use in both residential as well as commercial interiors to maintain its beauty in diverse environments.

Architectural Applications: This product is very effective in architectural projects that require both structural stability and aesthetic flexibility within them. Whether used for columns, beams or exterior cladding, Restructuring Tech-Wood exhibits consistent performance due to its strong bond with resistance against environmental factors.

Packaging Solutions: For upscale packaging applications; one can go for Restructuring Tech-wood, which is a strong and visually appealing option that provides incredible longevity when compared to others on the market today. Its water-resistant properties enable it to protect valuable goods during transportation besides storage as it boosts visual attractiveness of general presentation.

Construction Projects: In construction industry, durable decking materials as well as sidings made of weather resistant components such as this product called ‘’restructuring tech-wood’’ are used a lot by builders. Even after several decades spent into its use Reliable adhesion along with protection against moisture helps ensure long-lasting attractive structures.

White UF Resin Adhesive Powder FAQ:

What is Tech-Wood produced through Restructuring?

Tech-wood restructuring is made by processing and rearranging ordinary wood, especially fast growing species, with the use of urea formaldehyde resin glue. The outcome is a strong long lasting material that can resist weathering and can be used in various applications such as furniture making, construction among others.

How does Tech-Wood from Restructuring differ from normal wood?

Tech-wood restructuring has undergone some high-tech treatment and curing processes that enhance its strength, weather resistance and beauty. This makes it more effective than normal wood in areas with a lot of moisture or temperature fluctuation.

What are the possible uses for Restructuring Tech-Wood?

Our restructuring tech-wood is best suited for furniture production, interior decoration, architectural components, packaging solutions as well as different constructions where it is highly valued for durability, versatility and meeting diverse aesthetic requirements.

How does urea-formaldehyde resin adhesive improves the performance of Restructured Tech-Wood?

The urea-formaldehyde resin adhesive employed on our Restructured Tech-Wood, enhances its water resistance abilities plus moisture resistance hence increasing its lifetime. This ensures that wood fibers are firmly bonded together thus producing a product which can survive harsh environmental conditions.

Is Restructured Tech-Wood environmentally friendly?

Yes, restructured tech-wood is manufactured using sustainable practices which may include use of fast growing timber species. The manufacturing process also reduces its impacts on environment making it a green choice for multiple applications.