High-Strength Particleboard UF Resin Powder

- Product Information

The Particleboard UF Resin Powder is intended to increase the strength and stability of particleboard, which is a popular man-made board in woodworking. It involves slicing wood into chips of certain sizes, applying adhesive to them before hot pressing them together thereby forming a solid board that lasts long. The essential role played by our UF resin powder in this process cannot be ignored as it ensures strong bonding of the wooden particles thus resulting into more resilient and stable end products.

We are dedicated to offering quality adhesives that suit our clients as one of the foremost China particleboard UF resin powder supplier. Our Particleboard UF Resin Powder not only improve mechanical properties of particleboards but also guarantees durability and performance under different conditions. Regardless if you manufacture particleboards for furniture making, construction or other uses, our resin powder will confer upon you dependable bonding strength.

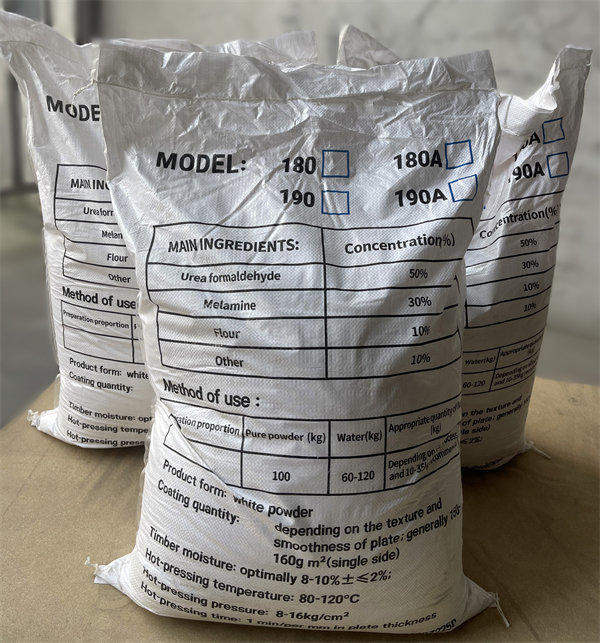

High-Strength Particleboard UF Resin Powder Parameters:

| Name | Urea Formaldehyde Resin Powder |

| Model | 180/180A |

| Shelf life | 1 year |

| Product form | white powder |

| Weight | 25kg |

| Timber moisture | optimally 8-10%±≤2% |

| Hot-pressing temperature | 80-120℃ |

| Hot-pressing pressure | 8-16kg/cm² |

| Hot-pressing time | 1 min/per mm in plate thickness |

| Performance | Boiled at 80℃ for 2.5 hours(180) / Boiled at 80℃ for 3.5 hours(180A) |

| Amount of curing agent added | 2-5‰ of the glue already blended |

| Without curing agent, activity period(180) | 24 hours |

| Industrial flour has been added, activity period(180A) | 24 hours |

| Without industrial flour and curing agent, activity period(180A) | 48 hours |

| Curing agent has been added, activity period | 3 hours |

| Coating quantity | depending on the texture and smoothness of plate, generally 150-180g m²(single side) |

High-Strength Particleboard UF Resin Powder Instructions For Use:

1. Prepare a container, stirring tools, and 25kg of room temperature water (add the water twice).

2. Dissolving glue powder:

First pour 15kg of water into the container,

then pour 25kg of resin powder into the water and stir to dissolve.

Stir into a paste until the glue powder does not agglomerate,

then add the remaining 10kg of water and fully stir to form a glue solution.

3. The mixed glue is used after 1 hour of waiting, and the effect is the best.

4. According to the production requirements of the product process, it can be mixed with additives such as curing agent(Ammonium chloride) .

5. During use, increase or decrease the ratio of resin powder to water according to the moisture content of the board and the local climate.

6. Amount of industrial flour added: 20-25% of the glue already blended.(180A to add)

High-Strength Particleboard UF Resin Powder Features:

1. Exceptional Adhesive Power

Our Adhesive Powder is designed to offer exceptional adhesive power and thus ensure secure bonding of wood particles in the board. Such a strong bond improves its overall durability and stability, making it fit for various applications. Use our UF Resin Powder to be sure that you are getting the best product quality in the market.

2. Reinforced Strength

With the help of Particleboard UF Resin Powder, you will vastly strengthen your particle board’s structure integrity. It connects with fibers within the wood creating a very strong composite that makes boards more resistant to strain or bending deformation. Count on our UF Resin Powder for creating particleboards that can withstand harsh conditions and still maintain good quality.

3. High Volume Production Ready

The main objective behind developing our Particleboard UF Resin Powder was to make it efficient enough for mass production lines. Its easy-to-use powder formulation cuts downtime by speeding up production while maintaining quality, meaning more boards per time frame are produced with increased efficiency levels too using this powder from us called UF Resin Powder.

4. Flexible Uses

Our Particleboard UF Resin Powder has a wide range of uses as it suits different types of wood species and processing techniques applied in their production process. If you manufacture furniture, flooring or do construction, then use our UF Resin Powder as it guarantees reliable, repeatable performance.

5. Environmentally Friendly Manufacturing

While producing Particleboard UF Resin Powder, environmental responsibility is our priority. This ensures that manufacturers whom purchase this product will have minimum emissions into their surroundings.

High-Strength Particleboard UF Resin Powder Application:

Manufacture of Furniture: It is best suited for manufacturing durable and cost-effective particleboard that is used in furniture such as cupboards, shelves, and tables. For a better longevity of this furniture withstanding daily wearing out effect it ensures a strong bond between wood particles our Particleboard UF Resin Powder.

Flooring Solutions: It can be used to produce the particle board which is used as base layer in flooring systems. The flooring remains stable and durable due to its excellent bonding strength on our UF Resin Powder, therefore it resists heavy foot traffic or other stresses.

Construction Panels: This is perfect for making particle board panels for walls, ceilings and partitions in building constructions. These panels will remain structurally reliable when subjected to internal pressures since we adhere them with our Particleboard UF Resin Powder hence they can be trusted both for residential and commercial projects.

Decorative Elements: Our product also makes the decorative elements like moldings, trims, face boards among others from particle board which are consistent in quality because of using good amount of UF Resin Powder that gives it power support.

Packaging Materials: Our product can also be applied in production of packaging materials such as boxes made from particleboard material meant for packing products like crates among others, these materials will last long due to their ability resist impacts during transportation or storage rendered by our Particle Board UF resin powder.

High-Strength Particleboard UF Resin Powder FAQ:

What is the Particleboard UF Resin Powder used for?

Our Particleboard UF Resin Powder is utilized in bonding wooden particles when making particleboards. This ensures that the boards are strong, durable and stable for a range of applications including furniture, flooring as well as construction panels.

How does Particleboard UF Resin Powder enhance strengthening of particleboard?

The manufacturing process allows the resin powder to penetrate into the wood fibers, which then forms a strong bond that enhances the overall structural integrity of the particleboard thereby making it more stress-resistant and deformation-proof.

Is your Particleboard UF Resin Powder suitable for all types of wood particles?

Yes, our Particleboard UF Resin Powder is versatile and compatible with various types of wood particles such as hardwoods, softwoods and mixed wood particles hence ensuring average performance across different particle board products.

Can I use Particleboard UF Resin Powder in high-humidity environments?

Our Particleboard UF Resin Powder is designed to work well in different environmental conditions such as areas with high humidity. It forms a strong bond maintaining its shape even under moisture attack on the particle board.

Is there anything eco-friendly about Particleboard UF Resin Powder?

Yes, we have sustainability as our focus in our products; thus our Particleboard UF Resin Powder has low emissions and minimal environmental footprint making it an environmentally friendly choice for manufacturers.

How should you store Particleboard UF Resin Powder?

Keep your Particleboard UF Resin Powder in a cool dry place, away from direct sunlight and moisture to maintain its effectiveness and extend its shelf-life.