Melamine Impregnated Paper MUF Resin Powder

- Product Information

Our Melamine Impregnated Paper Muf resin powder is a top-tier product tailored for the wood and furniture industry, where it is subjected to tough operating conditions. As a specialized Chinese maker of impregnated paper muf resin powder, we have developed a resin powder that has superior adhesion properties such that impregnated paper can bond seamlessly with various substrates like particle boards, MDF and plywoods. This product is well known for its outstanding performance which makes durability, heat resistance and smooth finish enhancing the beauty of the final products.

Our Impregnated Paper MUF Resin Powder are carefully engineered to provide consistent results as it is preferred by manufacturers who want reliability in their production process. The resin powder is easy to apply and cures quickly allowing for a streamlined manufacturing process without compromising on quality. We know how important resin powder is in the making of high-quality laminated boards and our product has been designed with this criteria in mind.

Being among the leading China Impregnated Paper MUF Resin Powder Manufacturer, we aim at producing products that surpass customers’ expectations while meeting the requirements set by their respective industries. Our state-of-the-art technology ensures that our resin powders are made from every single batch which meets all required quality standards. Thus being named an honorable Impregnated Paper MUF Resin Powder Manufacturer because our solutions work effectively, they are also sustainable hence making sure our clients prosper competitively within wood and furniture markets.

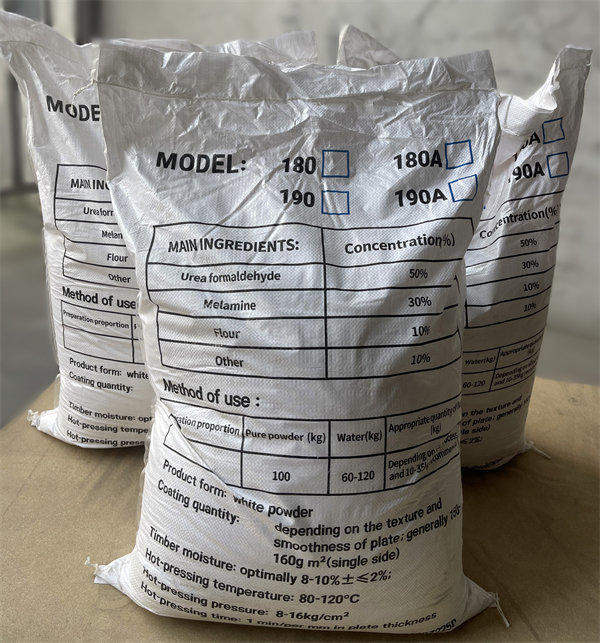

Melamine Impregnated Paper MUF Resin Powder Parameters:

| Name | Melamine Urea Formaldehyde Resin Powder |

| Model | 190/190A |

| Shelf life | 1 year |

| Product form | white powder |

| Weight | 25kg |

| Timber moisture | optimally 8-10%±≤2% |

| Hot-pressing temperature | 80-120℃ |

| Hot-pressing pressure | 8-16kg/cm² |

| Hot-pressing time | 1 min/per mm in plate thickness |

| Performance | Boiled at 100℃ for 4 hours(190) / Boiled at 100℃ for 6 hours(190A) |

| Amount of curing agent added | 2-5‰ of the glue already blended |

| Without curing agent, activity period | 24 hours |

| Without industrial flour and curing agent, activity period(190A) | 48 hours |

| Curing agent has been added, activity period | 3 hours |

| Coating quantity | depending on the texture and smoothness of plate, generally 150-180g m²(single side) |

Melamine Urea-Formaldehyde Resin Powder Instructions For Use:

1. Prepare a container, stirring tools, and 25kg of room temperature water (add the water twice).

2. Dissolving glue powder

First pour 15kg of water into the container,

then pour 25kg of resin powder into the water and stir to dissolve.

Stir into a paste until the glue powder does not agglomerate,

then add the remaining 10kg of water and fully stir to form a glue solution.

3. The mixed glue is used after 1 hour of waiting, and the effect is the best.

4. According to the production requirements of the product process, it can be mixed with additives such as curing agent(Ammonium chloride) .

5. During use, increase or decrease the ratio of resin powder to water according to the moisture content of the board and the local climate.

6. Amount of industrial flour added: 20-25% of the glue already blended.(190A to add)

Melamine Impregnated Paper MUF Resin Powder Features:

1. Well built/strong and resists impact

With our Impregnated Paper Adhesive Powder, we ensure that impregnated paper is more durable hence it would be able to withstand high-impact environments without affecting quality. This makes it suitable for long-lasting and strong applications. Trust on our Impregnated Paper MUF Resin Powder to offer exceptional performance thus ensuring your products remain reliable over time.

2. Better surface stability

Our Impregnated Paper MUF Resin Powder greatly improves surface stability such as reducing warping and deformation risks. Thus, this characteristic is essential in laminated surfaces’ aesthetic and functional integrity particularly in high humidity or temperature varying atmospheric conditions. Depend on us for smoothness that never changes due to our Melamine Urea Formaldehyde Resin Powder.

3. Multipurpose Applications

We manufacture our Melamine urea formaldehyde resin powder with great versatility so it suits various applications including furniture, flooring, and decorative laminates. Our Impregnated Paper MUF Resin Powder is a product which can be used for creating different types of finishes including high-gloss or textured ones hence providing flexibility and accuracy in every project.

4. Uniform Quality/ Consistency in Quality and Performance

It’s all about consistency when it comes to manufacturing processes. It guarantees consistent quality across all your production lines since each batch of our *Impregnated Paper MUF Resin Powder has been made uniformly throughout its manufacturing process.. Expect the same outcome from using our Melamine Urea Formaldehyde Resin Powder, as this will enhance your product’s reliability leading to customer satisfaction.

5. Affordable And Time Saving

Efficiency matters a lot in manufacturing industry thus our Impregnated Paper MUF Resin Powder is aimed at achieving that by reducing wastage and lowering costs. The high reactivity and superior bonding properties of our Melamine Urea Formaldehyde Resin Powder facilitate faster curing times, which means high throughput yet maintaining quality standards.

Melamine Impregnated Paper MUF Resin Powder Application:

1. High-Pressure Laminates (HPL)

Our Melamine Impregnated Paper MUF Resin Powder is extensively used in the production of high-pressure laminates. These laminates are ideal for surfaces requiring superior durability, such as kitchen countertops, workstations, and wall panels. The powder enhances the paper’s resistance to impact, moisture, and heat thereby making it a reliable choice for heavy traffic areas.

2. Furniture Manufacturing

In furniture industry our Impregnated Paper MUF Resin Powder, helps in developing aesthetically pleasing as well as durable surfaces. It is employed to make decorating laminates which cover items like closets, tables, and wardrobes among others. As such a user will enjoy using this furniture since it does not lose its appearance even if used daily.

3. Flooring Solutions

For flooring applications our Melamine Urea Formaldehyde Resin Powder offers strength and stability to the laminate surface. It is often applied in manufacturing of laminated floors that resist scratching or staining from spills hence suitable for use in both residential and commercial spaces

4. Decorative Panels

The creation of decorative panels made from our Impregnated Paper MUF Resin Powder, by interior designers are widely accepted by architects all over the world. Some popular spots where these panels are seen include offices hotels and other retail outlets that need to have attractive yet long lasting walls’. Hereby ensuring that the panel maintain their bright colors as well as patterns tough conditions notwithstanding.

5. Door Skins

Our melamine urea formaldehyde resin powder is also used in creating door skins. Thus these decorative overlays offer doors with an attractive and long lasting finish that resists scratching, denting and other forms of damage. This is especially significant in areas such as commercial buildings and apartment blocks where demand for door skins is high.

Melamine Impregnated Paper MUF Resin Powder FAQ:

What do people use Melamine Impregnated Paper MUF Resin Powder?

Mainly, our Melamine Impregnated Paper MUF Resin Powder is used in manufacturing decorative laminates, high-pressure laminates, and flooring. For furniture, wall panels, door skins and others; it is providing better durability, impact resistance and surface stability.

What are the main advantages of using your MUF Resin Powder?

Some of the key benefits include enhanced impact resistance, excellent surface stability, improved durability and cost-effectiveness. Our MUF Resin Powder provides consistent quality in laminated products which makes it suitable for high-traffic as well as demanding environments.

Can your company’s MUF resin powder be used in both residential and commercial applications?

Yes indeed! Certainly! Absolutely! Definitely! Positively!

Our Muf resin powder might be employed within a broad range including but not limited to those who want it for their homes either as flooring or furniture upholstery purposes as well as for commercial interior designing purposes such as wall panels or other areas. It works dependably in many different settings.

What are the types of papers used with your MUF resin powder?

Our MUF Resin Powder can be used on plain base paper and printed decorative paper as well. For this purpose, it is compatible with a variety of paper types, ensuring high bonding strength and an excellent finish.