High-Strength Corrugated Board UF Resin Powder

- Product Information

Our High-Strength Corrugated Board UF Resin Powder is a powerful solution that improves the quality of corrugated board considerably. This resin powder contains urea-formaldehyde adhesives which are extremely strong, ensuring that the corrugated board will not collapse under pressure even when it is subjected to heavy loads. Moreover, our Corrugated Board UF Resin Powder has higher water and moisture resistance making it ideal for use in humid areas. These additional features guarantee that the corrugated board stays intact and lasts longer than before thus increasing its life span of usage. Being a dependable China Corrugated Board UF Resin Powder Supplier, we are committed to producing uniform quality and performance every time. Our product is designed to satisfy the specific needs of the industry with reliability in each application process. For a competitive quote, contact us now and discover how our Corrugated Board UF Resin Powder can help you improve your production processes as well as products on offer.

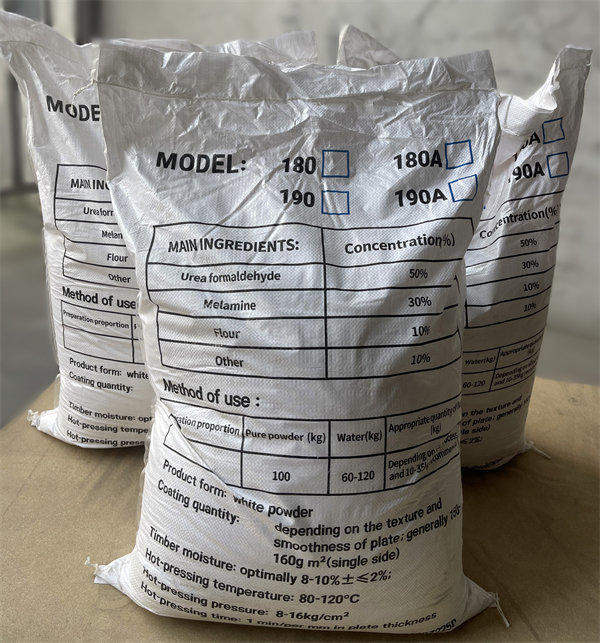

High-Strength Corrugated Board UF Resin Powder Parameters:

| Name | Melamine Urea Formaldehyde Resin Powder |

| Model | 190/190A |

| Shelf life | 1 year |

| Product form | white powder |

| Weight | 25kg |

| Timber moisture | optimally 8-10%±≤2% |

| Hot-pressing temperature | 80-120℃ |

| Hot-pressing pressure | 8-16kg/cm² |

| Hot-pressing time | 1 min/per mm in plate thickness |

| Performance | Boiled at 100℃ for 4 hours(190) / Boiled at 100℃ for 6 hours(190A) |

| Amount of curing agent added | 2-5‰ of the glue already blended |

| Without curing agent, activity period | 24 hours |

| Without industrial flour and curing agent, activity period(190A) | 48 hours |

| Curing agent has been added, activity period | 3 hours |

| Coating quantity | depending on the texture and smoothness of plate, generally 150-180g m²(single side) |

High-Strength Corrugated Board UF Resin Powder Instructions For Use:

1. Prepare a container, stirring tools, and 25kg of room temperature water (add the water twice).

2. Dissolving glue powder

First pour 15kg of water into the container,

then pour 25kg of resin powder into the water and stir to dissolve.

Stir into a paste until the glue powder does not agglomerate,

then add the remaining 10kg of water and fully stir to form a glue solution.

3. The mixed glue is used after 1 hour of waiting, and the effect is the best.

4. According to the production requirements of the product process, it can be mixed with additives such as curing agent(Ammonium chloride) .

5. During use, increase or decrease the ratio of resin powder to water according to the moisture content of the board and the local climate.

6. Amount of industrial flour added: 20-25% of the glue already blended.(190A to add)

High-Strength Corrugated Board UF Resin Powder Features:

1. Better Strength and Durability

Specifically engineered to improve the structural integrity of corrugated board, our High-Strength Corrugated Board UF Resin Powder is designed to offer good bonding strength and insure that your corrugates remain durable and resilient under heavy loads. Trust our UF Resin Powder to deliver strong performance each time.

2. Great Water and Moisture Resistance

Among the best features of our Corrugated Board UF Resin Powder is its superior water and moisture resistance. It means that even in humid areas, your corrugates will maintain their strength and stability, reducing risks such as warping or decay. For protection against moisture damage, we suggest using our UF Resin Powder.

3. Longer Product Lifespan

When you use our Corrugated Board UF Resin Powder, it not only enhances the immediate strength of your corrugates but also extends their overall life span. Increased moisture resistance combined with structural stability ensures that your products last longer, providing more value and reliability for customers.

4. Consistent Quality And Performance

We are aware of how important consistency in manufacturing is. We produce our Corrugated Board UF Resin Powder in accordance with strict standards resulting in uniform quality for every batch manufactured. By having consistent batches you can predict high-quality outcomes in production processes thus giving an assurance about the final product.

5. Reasonable Cost/Time Effective

Our Corrugated Board UF Resin Powder is built to maximize production efficiency for you. Through faster cure times enabled by high reactivity coupled with strong bonding capabilities there is decreased wastage ultimately lowering costs while maintaining outstanding product quality during production stage thus rely on this type of powder.

High-Strength Corrugated Board UF Resin Powder Application:

1. Heavy-Duty Packaging

Our Corrugated Board UF Resin Powder is ideal for manufacturing corrugated cardboard used in heavy-duty packaging. It is perfect for delivering on the big and bulky items that require strong and resilient packaging. This will make your products to be well protected during transit even under difficult times.

2. Moisture-Resistant Storage Solutions

Our UF Resin Powder has unmatched water-resistant properties, which are desirable for industries like food and beverage storage where moisture resistance is important. Our resin-treated corrugated boards remain intact without any warping, thus ensuring that merchandise kept under humid conditions are secure and undamaged.

3. Industrial and Commercial Displays

The use of our Corrugated Board UF Resin Powder, therefore, ensures they are stable and long-lasting in industrial and commercial display units production. Stability and strength provided by our resin powder maintain their appearance and functionality over time making these displays useful especially in places with high traffic as well as there being various climatic changes.

4. Retail Packaging

Moreover, our UF Resin Powder is commonly utilized in the manufacture of retail packaging solutions that need both strength and beauty enhancement. Our resin makes corrugated boards durable yet they can still hold more complex designs as well as prints suitable for retail packaging that requires protection while also looking attractive.

5. Furniture Manufacturing

In furniture making industry, our manufacturers use this product to develop light yet strong components such as drawers or cabinets using the lightweight yet highly rigid nature of the resin; therefore, it applies to different types of furniture ranging from storage cabinets to decorative panels.

Corrugated Board Uf Resin Powder FAQ:

What is Corrugated Board UF Resin Powder used for?

Our Corrugated Board UF Resin Powder primarily adds strength, durability and moisture resistance to corrugated cardboard, making it suitable for heavy-duty packaging, industrial displays, and applications where moisture damage needs to be prevented.

How does your UF Resin Powder improve the quality of corrugated boards?

Our UF Resin Powder provides excellent bonding strength and moisture resistance that ensures stable and strong corrugated boards even in high humidity conditions thus improving the lifespan and performance of the same.

Can your UF Resin Powder be used in environmentally sensitive areas?

Yes it can. Our UF Resin Powder has been designed such that its environmental impact is reduced thus making it a good choice for those applications where sustainability and environmental responsibility are important factors.

How does your UF Resin Powder contribute to moisture resistance?

Moisture will not penetrate through our Corrugated Board UF Resins Powders; therefore there will be no warping or water absorption on the sides of the board which makes them an ideal choice especially in areas with humid or wet conditions.

Can your UF resin powder work on different types of corrugated board?

Absolutely! Our products are versatile and can be used with all kinds of corrugated boards out there including those for packaging, display, furniture components thereby giving you their consistent strength across various applications.